A meticulous quality control structure that integrates development and production departments

In our R&D department, we always try not only to ensure the level of quality required for mass production, but also to reduce the lead time from development to production so that we can identify problems and give feedback as early as possible.

At our factory, our production staff concentrate their skills on quality process control. In our quality control structure, each staff member is responsible for building up quality meticulously at each stage in fabricating and assembling thousands of parts into a QSS system. In addition, we immediately put ideas from the shop floor into action. This enterprising corporate culture encourages us to continuously improve our production equipment and system, thus ensuring a high level of quality that meets our customers’ expectations.

Medical device production

As per the Pharmaceutical and Medical Device Act, a license needs to be obtained for companies to manufacture and sell medical devices. We obtained that license in 2011. And in 2013, we became the first in Wakayama Prefecture to obtain a license to manufacture and sell Class I medical devices. We will continue to contribute to society through the power of manufacturing, maintaining high quality.

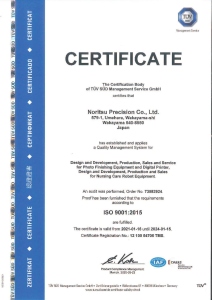

Certified with ISO 9001 and ISO 13485

We obtained ISO 9002 international quality management standard certification in 1993. Being among the first to try to ensure quality control that meets international standards, we also obtained ISO 9001 certification, which applies to all services associated with design, development, and production, in 2003.

We obtained ISO 9002 international quality management standard certification in 1993. Being among the first to try to ensure quality control that meets international standards, we also obtained ISO 9001 certification, which applies to all services associated with design, development, and production, in 2003.

Furthermore, in 2015, we obtained ISO 13485 certification, a quality management system standard for medical devices, and continuously strive to improve quality control.